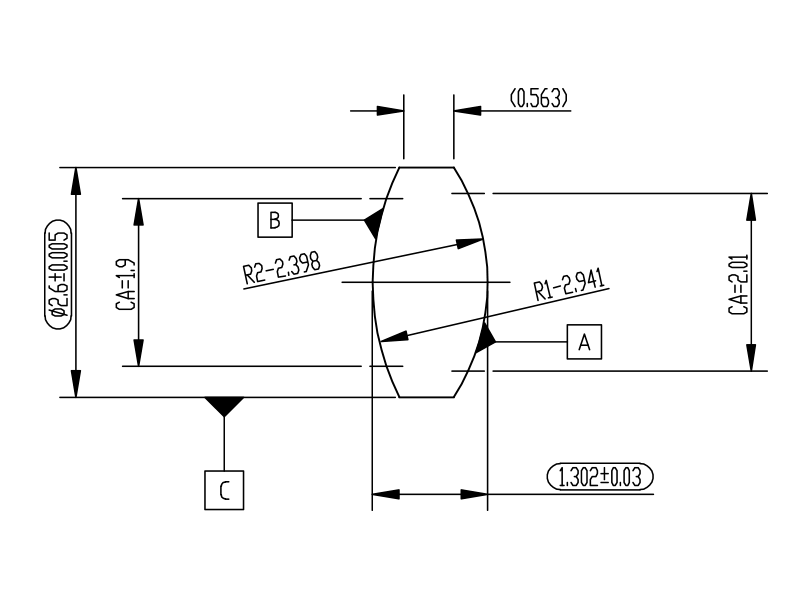

| Diameter | <Ø10mm | Ø10mm~Ø15mm | Ø15mm~Ø25mm | Ø25mm~Ø50mm | >Ø50mm |

| Profile error(PV) | <1um | <1.5um | <3um | <10um | <25um |

| Decenter | <2um | <2.5um | <5um | <8um | <15um |

| Center thickness tolerance | <±5um | <±10um | <±20um | ||

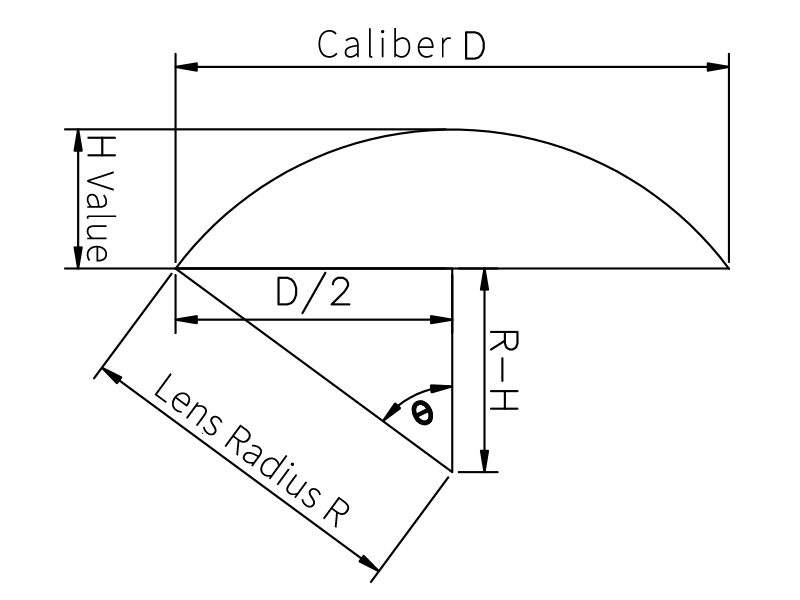

| Shape | <Ø(mm) | R Value | Open Angle |

| concave | <3.4 | >1.8 | <145° |

| convex | >2.6 | >2 | <145° |

© Young Optics Inc. Design by GTUT